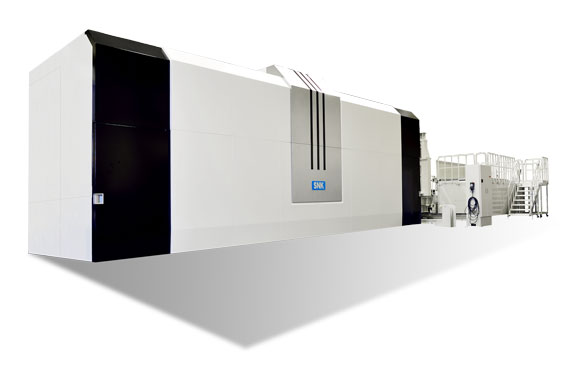

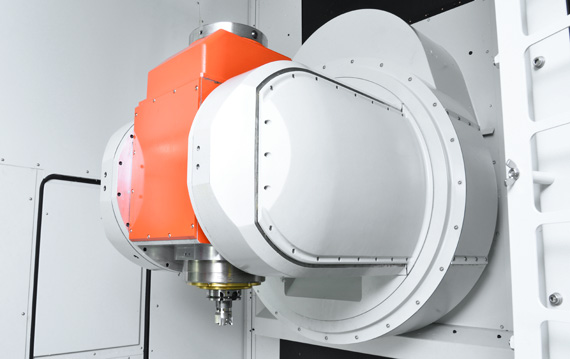

HPS-Pro Series

High-Speed 5-Axis Profilers

HPS-PRO Series

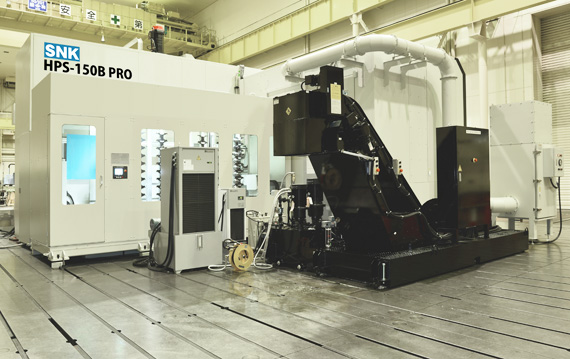

The new standard in high-speed 5-axis aerospace airframe machining

Introducing SNK’s PRO Series high-speed 5-axis machining centers. Designed to meet the aerospace industry’s growing demand for monolithic components, these revolutionary machines enable a quantum leap forward in the machining of medium-to-large complex aluminum aerospace parts. Their powerful, high-speed spindles combined with blazing rapid feedrates take metal removal rates and productivity to new heights while maintaining SNK’s long-standing tradition of solid value. Enhanced axes movements allow for expanded 5-axis simultaneous contouring capability. Available in sizes to suit your requirements.

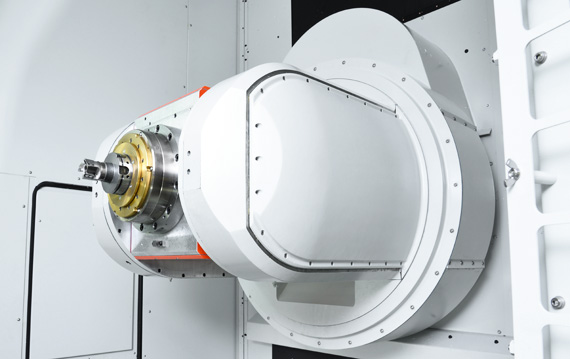

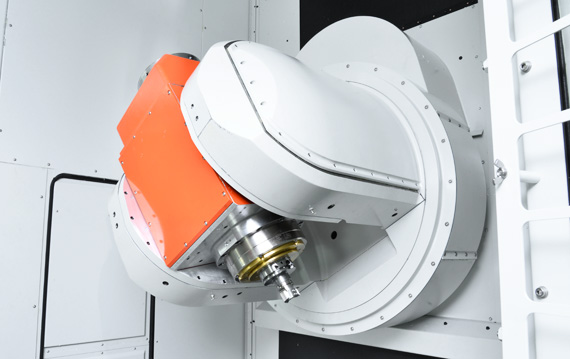

- Powerful, high-speed Spindles

-choice of 114 hp 20,000 rpm or 134 hp 30,000 rpm

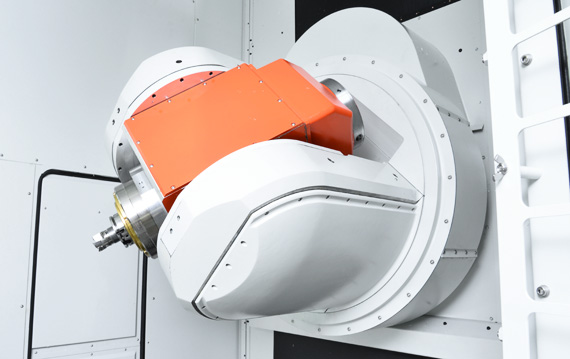

-outstanding metal removal rates - Wide A and C Axes Movement

-A-axis +/-100 deg; C-axis continuous

-enhanced 5-Axis simultaneous machining capability and back-angle cutting - 1,575 in/min rapid feed boosts productivity

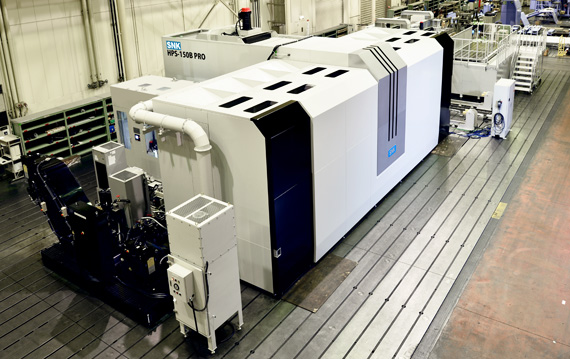

- Horizontal design for unrivaled chip evacuation

-optimizes tool life

-minimizes thermal distortion due to chip build-up - SNK’s exclusive DCS-VII Aero Software

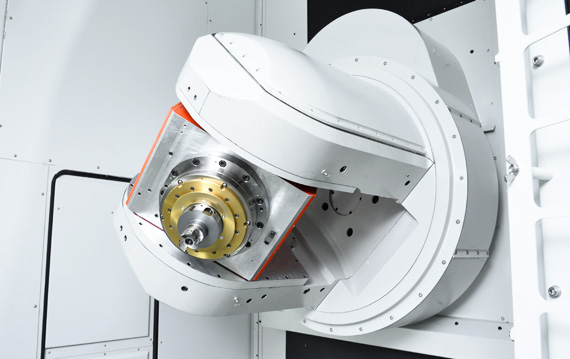

-high-speed, high-precision machining with unparalleled surface finishes - Ultra-rigid pallet support and clamping system

-unparalleled rigidity under heavy cutting loads

-optimizes accuracy and surface finishes

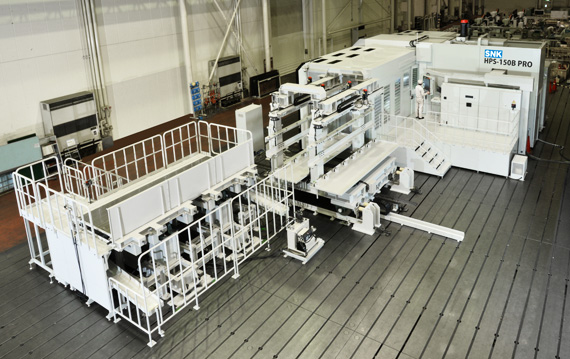

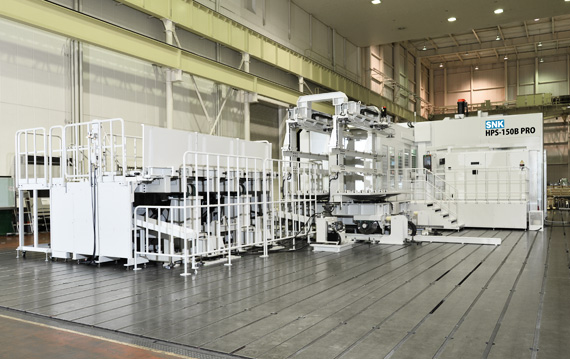

-enables heavier pallet load capacity - External Tilting Table Pallet Load Station

-side delivery system enables multiple machine pallet feed

-tilting table design simplifies workpiece loading/unloading

-flexible floor plan layouts to suit your facility - Flexible system expansion capability

-add machines as your needs grow

-no need to purchase additional palletizing stations

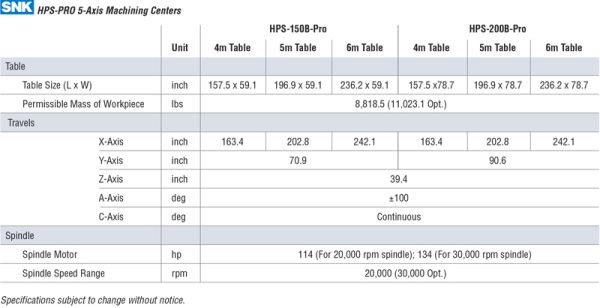

HPS-PRO Series Specifications

Literature Request

[wpforms id=”2117″ title=”false” description=”false”]