High Performance Machines

for Construction Industry Manufacturing

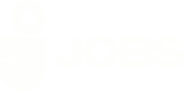

HF SERIES

Extra-Large Capacity Double Column 5-Face Machining Centers

- Extra-large capacity and extreme power streamlines machining of virtually any size workpiece utilized in large construction and mining industry manufacturing

- Wide variety of attachments maximizes machine flexibility and improves productivity

- Fully automated, temperature controlled lubrication system minimizes thermal displacement

- Conversational type automatic programming system allows for easy operation by facilitating five-face machining programming

Table Size (W x L): 59″ x 157″ to 236″ x 1,141″

Distance from Table to Spindle End: 68″ to 314″

Table Load Capacity: 33,075 to 132,300 lbs

Also available in larger sizes

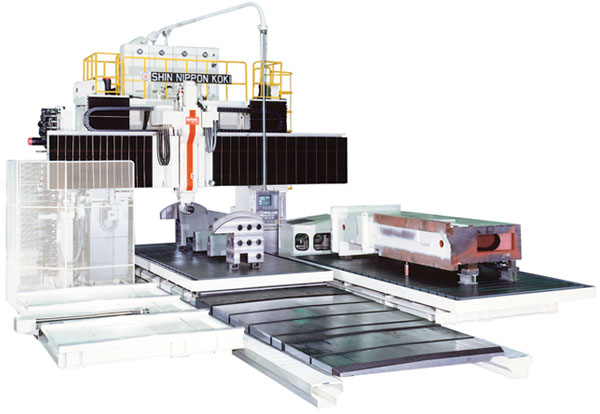

GMB SERIES

Extra-Large Capacity Gantry Type Double Column 5-Face Machining Centers

- Generous spindle to table distances

- Available in fixed and moving crossrail (W-Axis) models

- High-productivity Dual Work Zone design permits work set-up on one zone while machining work on other zone

- AAC and ATC designed to service both work zones

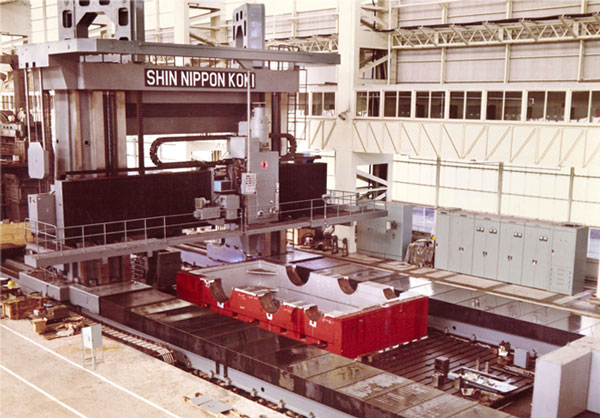

NeoV SERIES

High Speed, High Power Double Column 5-Face Machining Centers

- Power and capacity to handle tough cutting conditions. Ideal for castings and forgings

- Wide selection of attachments simplify machining of large multi-faceted components and deep cavities

- Heavy duty Z-Axis design incorporates twin ball screws for unrivaled rigidity and accuracy

Table Size (W x L): 59″ x 118.1″ to 157.5″ x 315.0″

Distance from Table to Spindle End: 70.6″ to 157.0″

Table Load Capacity: 33,000 to 88,000 lbs

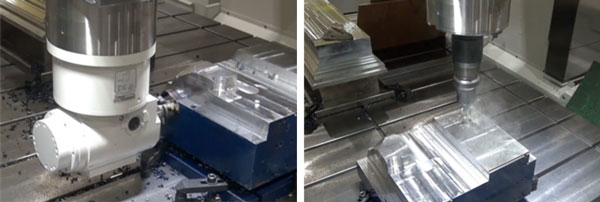

RB-MII SERIES

Large Capacity Double Column 5-Face Machining Centers

- Extra-wide and extra-long tables

- Attachments designed for machining large multi-faceted workpieces and deep cavities

- Cost-effective choice for large component machining

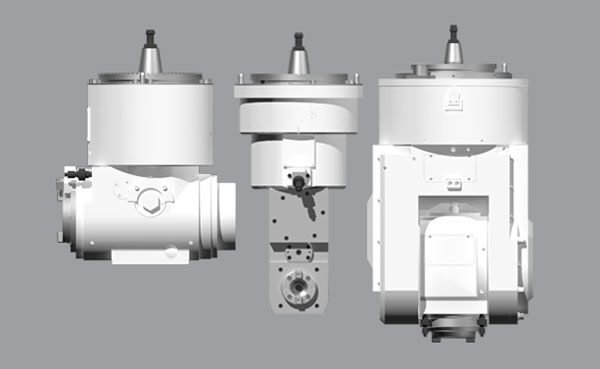

KRS230H

Special Purpose, Dual Spindle Horizontal Machining Cell

- 2 opposing spindles simultaneously machine both sides of workpiece

- Ideal for machining construction equipment components

- 5-face machining capability with available indexing table and 90 degree spindle attachments

IKEGAI

Large Capacity Turning Centers

- Rigid structure with flat, wide beds built for heavy cutting

- High-precision headstock with thermal balance function

- Adjustable control panel for operator convenience

- Ideal for a wide variety of turning processes

- Large diameter built-in center standard on tailstock

EVER Series

Gantry Mills

- Compact design saves floor space

- High-rigidty

- Flexible in application

- Exceptional acceleration and speed

FRAZER Series

Horizontal Milling Centers

- Ideal for machining complex surfaces

- High-volume chip removal

- Available with traversing table as well as rotary table

- Compact design, full enclosure