BRIDGE TYPE 5-SIDED MACHINING

VERTICAL 5-AXIS MACHINING

HORIZONTAL 5-AXIS MACHINING

HORIZONTAL UNIVERSAL MILLING

BRIDGE TYPE 5-SIDED MACHINING

VERTICAL 5-AXIS MACHINING

HORIZONTAL 5-AXIS MACHINING

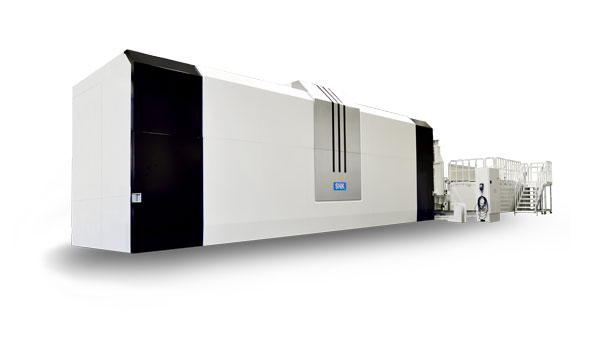

GANTRY TYPE

HORIZONTAL UNIVERSAL MILLING

SPECIAL APPLICATION MACHINES